Moglice

Find the right product solutions

Find the right product solutions

Any type of slideway for new production or overhaul. It can be puttied, poured or injected and is the essentially price worthier than any conventional system.

The result is:

• 1:1 correct to the micron with high wear resistance

• easily coated with perfect long term adhesion

• best damping properties = improvement of stiffness

• scatter-free start = optimized Anti Stick-Slip behavior

Fields of Application:

• round bushings

• slide bearings of any kind in large machine tools

• hydraulic pistons

• keyways

• column ways

• carriage slideways

• tooth racks

• ram guides

• hydrostatic guides

• support guideways

• aerostatic bearings

• deep hole bushings

• and many more guideways

DIAMANT moglice enables dynamic elements, e.g. slideways to run easily, protects from wear & tear and lowers buying as well as running costs. High wear resistance and improved stiffness are just 2 highlights of DIAMANT moglice.

Metal, what else do you need?

DIAMANT moglice does not change its Anti-Stick-Slip properties even under unfavourable conditions such as inadequate lubrication or high loads. When used on cast iron the friction value at rest, for example, is only about 1/7 of the conventional cast iron/steel pairing.

Survey of further benefits:

• applicable in place without special knowledge,

• high dimensional stability, shrinkless cure

(hardly measurable)

• optimum adhesion (individual coatings)

• wear proof even after decades

• easily moulded or injected.

Ready! – after cure.

• rational & rapid, with high long term results.

There is always an exact moulding from the precision ground bred- counterways after alignment.

The Consequences:

Excellent running properties, free of Stick-Slip with high stability and hardly measurable wear.

DIAMANT Moglice has been used Worldwide … by leading machine makers, machine tool builders with the

• putty moulding method

• injection method

• for way constructions and overhauls

Moglice 628 is an advanced, two-part repair epoxy, specifically engineered for restoring and upgrading machine tool guideways, slides, and bearings. Characterized as a semi-fluid having a consistency of a thin putty, it tends to run on a vertical surface with minimal damming, making it suitable for larger or less confined applications.

Low friction slideways

Slideways repair coatings

Bushings

Lead screw nuts

Spheres

Hydrostatic bearings

Complex replicated running surfaces

Safety Data Sheets:

SDS Hardener

SDS Moglice 628 Resin

Moglice 628 1282

Moglice 1000 Semi is an advanced, two-part repair epoxy, specifically engineered for restoring and upgrading machine tool guideways, slides, and bearings. Characterized as a thin putty which will run on a vertical surface, it is commonly used on machines with large flatways because it is easier to flow in large quantities, ensuring efficient application.

Low friction slideways

Slideways repair coatings

Bushings

Lead screw nuts

Complex replicated running surfaces

Safety Data Sheets:

Hardener

Moglice 1000 Resin

Moglice 1000 Semi 1273

Moglice 1000 FL is an advanced, two-part repair epoxy, specifically engineered for restoring and upgrading machine tool guideways, slides, and bearings. This material is a fluid and can be injected or poured to achieve optimal application. It contains Teflon (PTFE), which contributes to its exceptional performance, resulting in a 25-30% reduction in friction compared to traditional bearing materials. Additionally, it provides added protection against moisture absorption, enhancing durability and longevity in diverse operating environments.

Low friction slideways

Slideways repair coatings

Bushings

Lead screw nuts

Complex replicated running surfaces

Safety Data Sheets:

Hardener

Moglice 1000 FL Resin

Moglice 1000 FL

Moglice 1000 Putty is an advanced, two-part, repair epoxy putty, specifically engineered for restoring and upgrading machine tool guideways, slides, and bearings. It functions as a moldable, low-friction way-liner to produce high-precision slideways with anti-stick-slip properties. This high-performance material offers exceptional wear resistance, ideal for filling voids and repairing damage. Formulated with Teflon, Moglice 1000 Putty significantly reduces friction, resulting in a 25-30% reduction in friction compared to traditional bearing materials.

Low friction slideways

Slideways repair coatings

Bushings

Lead screw nuts

Complex replicated running surfaces

Safety Data Sheets:

Hardener

Moglice 1000P Resin

Moglice 1000 Putty

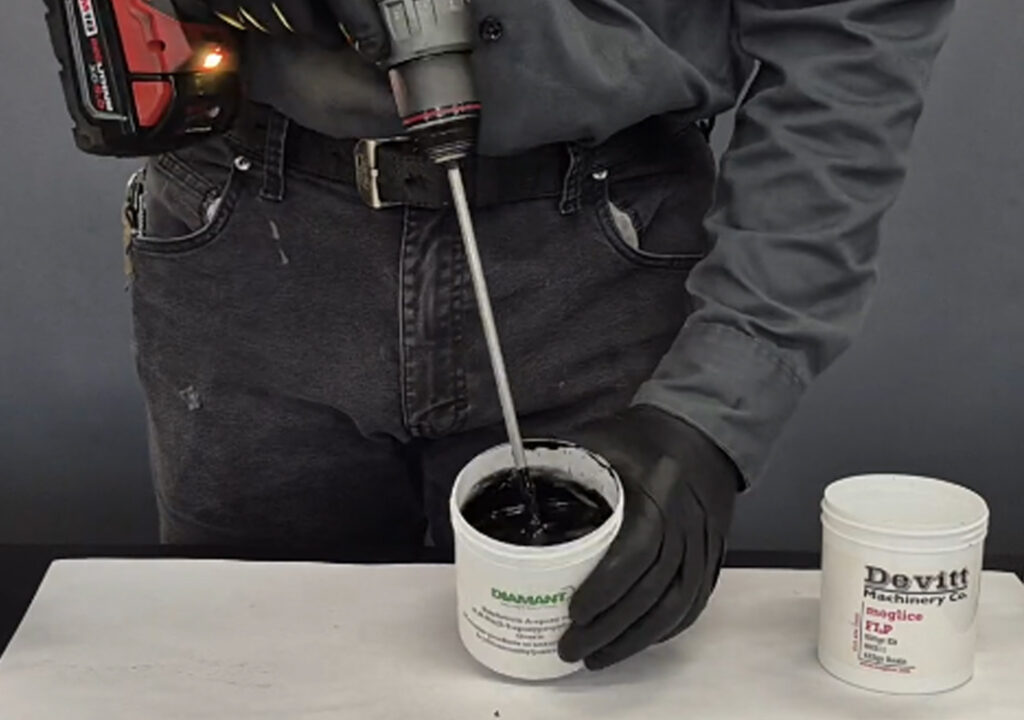

Moglice FLP is an advanced, two-part repair epoxy, uniquely formulated as a fluid with a consistency like motor oil. This allows it to be injected or poured, making it ideal for creating high-precision way systems, quill bores, nuts, or tapers. Utilized extensively in the pour and set application, Moglice FLP’s molding method enables the creation of complex forms and structures with micron-level accuracy.

Low friction slideways

Slideways repair coatings

Bushings

Lead screw nuts

Complex replicated running surfaces

Spheres

Hydrostatic bearings

Safety Data Sheets:

Hardener

Moglice FLP Resin

Moglice FLP

Moglice P500 is an advanced, two-part repair epoxy, uniquely formulated as a slightly thicker fluid with a consistency like honey. This consistency makes it ideal for precision applications. This product is specifically used for manufacturing guideways and hydrostatic guideways. It functions as a moldable, low-friction way-liner to produce high-precision slideways with anti-stick-slip properties.

Low friction slideways

Slideways repair coatings

Bushings

Lead screw nuts

Complex replicated running surfaces

Spheres

Hydrostatic bearings

Safety Data Sheets:

Hardener

Moglice 500 Resin

Moglice Putty Hard is an advanced, two-part repair epoxy, specifically engineered for restoring and upgrading machine ways, slides, and bearings. As a no-slump putty, it is the most common material used on standard way systems and can be easily applied to vertical and overhead surfaces without running or dripping. It functions as a moldable, low-friction way-liner to produce high-precision slideways with anti-stick-slip properties.

Low friction slideways

Slideways repair coatings

Bushings

Lead screw nuts

Complex replicated running surfaces

Spheres

Hydrostatic bearings

Safety Data Sheets:

Hardener

Moglice Putty Hard Resin

Moglice Putty Hard 0410

Score EX Cast Iron is the perfect material for small and medium surface repairs on cast iron. Due to its high number of fillers Score-EX Cast Iron has a fantastic metal finish and is machinable like cast iron. With its fast-curing time and flexible mixing ratio it is a very useful product for various types of industry.

Pot Life – 15 minutes

Cures – 45-60 minutes

IN THE KIT:

Score EX Powder

Score EX Liquid Hardener

1 Tablespoon

2 Tongue Depressors

Instructions

Safety Data Sheets

Score-Ex Cast Iron

Score-Ex Hardener

Example: 48″ Length x 5″ Width x .062″ Thickness = 14.88 cubic inches x 33 (FLP) = 491 Grams of Moglice Needed

Click the button below to download the Machine Tool Way Rebuilding Handbook. Requires Adobe Acrobat Reader to view.