DWH

Find the right product solutions

Find the right product solutions

DWH grades are designed for static fits in machine assembly, they do not include low-friction fillers. DWH resins are produced in various viscosities and have more than 80% metallic fillers. DWH is used to mold static machine components in-place and to eliminate expensive machining and scraping. It can also be used as repair material for maintenance. Its ability to mold to any shape makes it possible to shim with 100% contact.

Typical Applications

• all kinds of machine tools

• joints, grinding spindles, keyways

• guideways, bearing supports and flanges

• machine beds – bearings and bushings

Product Properties

• high precision true to measurement

• high bearing forces up to 120 N/mm2 (static)

• excellent damping and 100% forcefit

• 100% force transfer,

• excellent adhesion

• nearly no aging or weathering

• perfect exactness to the micron

• without costly machining or final working

Product Description

DWH is a fine adjustment coating system for connecting surfaces in machine elements and machine tools, omitting the expensive machining by the proven molding technology.

Benefits

DWH molds micron-exact in place making an exact copy of the surfaces the*** easy way.

The user can decide whether they want a firm adhesion or one that can easily be dismantled. When necessary for this, Separator is applied before molding.

DWH can be used for all metal elements which need to be long term, exact, resistant, adjusted, fixed & centered. This will improve stiffness

• guide pins and bushings are molded in place

• optimizing the stiffness

• screw holes are closed

• machine elements are centered

• element groups are fixed

All that without machining…

… and in 1 step with best damping properties and high cost savings guaranteed by the DIAMANT Fine Adjustment Coating System DWH for more than 5 decades, and not only in machine engineering.

More Benefits:

DWH can be used in place without special knowledge for any type of machine element.

And it is that easy:

1. roughen & clean adhesion surfaces

2. align

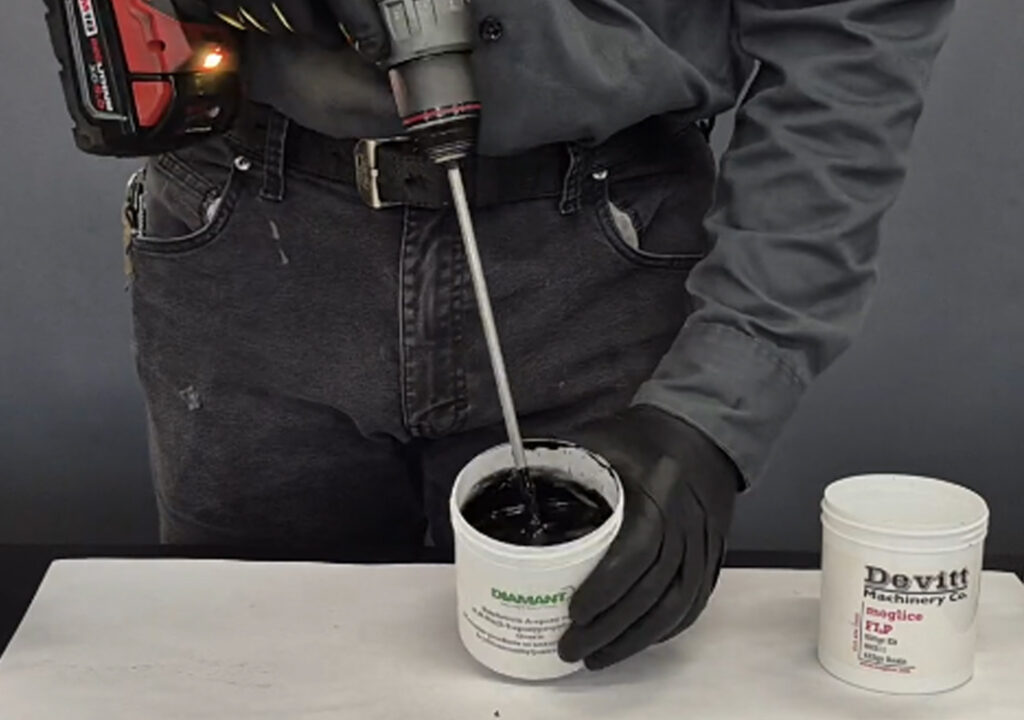

3. mix DWH

4. apply or inject

5. leave to cure and…

6. ready! exact to the micron.

Full DWH Product List Here

DWH 310 FL is a low-viscosity, two-part repair epoxy. Its formulation includes steel fillers, providing its characteristic grey color and ensuring an exceptionally robust and precise solution. DWH 310 FL proves invaluable in applications such as producing perfect bearing seats, achieving precise alignment of ball screws and columns to beds, and accurately locating hardened seats. It effectively addresses microscopic imperfections even on hardened, precision-ground surfaces, filling tiny voids to establish a critical 100% contact area. For ease of use, DWH 310 FL can be applied via injection or pouring.

Form- and force-fitting installation of guides in mechanical engineering

Adjusting coating for assemblies and elements of various materials.

Full-surface lining of moldings and elements as a replacement for feed plates.

Load-bearing gap compensation on beams of portal milling and Gantry systems

μm- precise molding of bushes, centering and guide elements

Fixing and / or centering of bearing bushes according to high precision alignment

As filling and composite material in 3D printing + additive Manufacturing

Safety Data Sheets:

Hardener 1473

310 FL

Technical Data Sheet:

310 FL

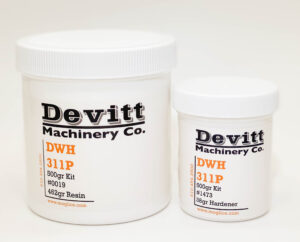

DWH 311 Putty is a thin, two-part repair epoxy putty. It’s formulated with aluminum fillers. It is particularly advantageous in applications where the sealing and injection method is less practical, such as on segmented surfaces. Thickening Powder is available for vertical and overhead applications.

Form- and force-fitting installation of guides in mechanical engineering

Adjusting coating for assemblies and elements of various materials.

Full-surface lining of moldings and elements as a replacement for feed plates.

Load-bearing gap compensation on beams of portal milling and Gantry systems

μm-accurate adjustment of bushes, centering and guide elements

Fixing and / or centering of bearing bushes according to high precision alignment

As filling and composite material in 3D printing + additive manufacturing

Very high accuracy, μm-accurate molding

Very high compressive strength

Extreme dimensional stability after curing

Excellent load transfer due to complete contact of the surfaces

Temperature resistance up to +80 °C

Excellent damping properties thanks to the E-module ca. 8600 N/mm²

Aluminum-grey color after curing

High resistance to oils, cooling emulsions, mineral and synthetic coolants and lubricates and many other chemicals.

Safety Data Sheets:

Hardener

311 P

Technical Data Sheet:

311 P

DWH 311 FL is a low-viscosity, two-part repair epoxy. It features aluminum fillers, contributing to its lower specific weight while maintaining robust performance. DWH 311 FL is particularly effective for filling keyways and bolt holes. Much like its cousin Moglice FLP, DWH 311 FL can be injected or poured depending on what the job calls for.

Form- and force-fitting installation of guides in mechanical engineering

Adjusting coating for assemblies and elements of various materials.

Full-surface lining of moldings and elements as a replacement for feed plates.

Load-bearing gap compensation on beams of portal milling and Gantry systems

μm- precise molding of bushes, centering and guide elements

Fixing and / or centering of bearing bushes according to high precision alignment

As filling and composite material in 3D printing + additive Manufacturing

Very high accuracy, μm-precision molding

Very high compressive strength

Extreme dimensional stability after curing

Excellent load transfer due to complete contact surfaces

Temperature resistance up to +80°C

Excellent damping properties due to the E-module ca. 8700 N/mm2 steel grey shade after curing

High resistance against cooling emulsions, mineral and synthetical coolants, lubricants and cutting materials

Safety Data Sheets:

Hardener

311 FL

Technical Data Sheet:

311 FL

DWH 316 Putty is a highly viscous, two-part repair epoxy putty, fortified with mineral fillers, engineered as a precision alignment system for a wide range of machinery. Despite its putty consistency, DWH 316 Putty can still be precisely injected after mixing, making it incredibly versatile. It is commonly utilized to realign critical components such as air bushings, bearings, and joint faces, directly reducing the need for costly machining. This innovative in-place molding technique ensures micron-level precision, resulting in an exact replica of the tool surface for superior alignment.

All type of gantry machines

Joints, spindle shafts, key slots

Guide rails, bearing chairs and flanges, machine beds

Bearing and index bushes

High Accuracy

High load carrying capacity [160 N/mm²]

Excellent shock attenuation

Full contact of mating surfaces and therefore good transmittal load

High damping capacity

Good adhesion with nearly zero aging

Precision down to the micron without expensive machining or finishing work

Safety Data Sheets:

Hardener

316

Technical Data Sheet:

316 Putty

Example: 48″ Length x 5″ Width x .062″ Thickness = 14.88 cubic inches x 31 (FL) = 461 Grams of DWH Needed

Click the button below to download the Machine Tool Way Rebuilding Handbook. Requires Adobe Acrobat Reader to view.